Quality Health Safety Environment

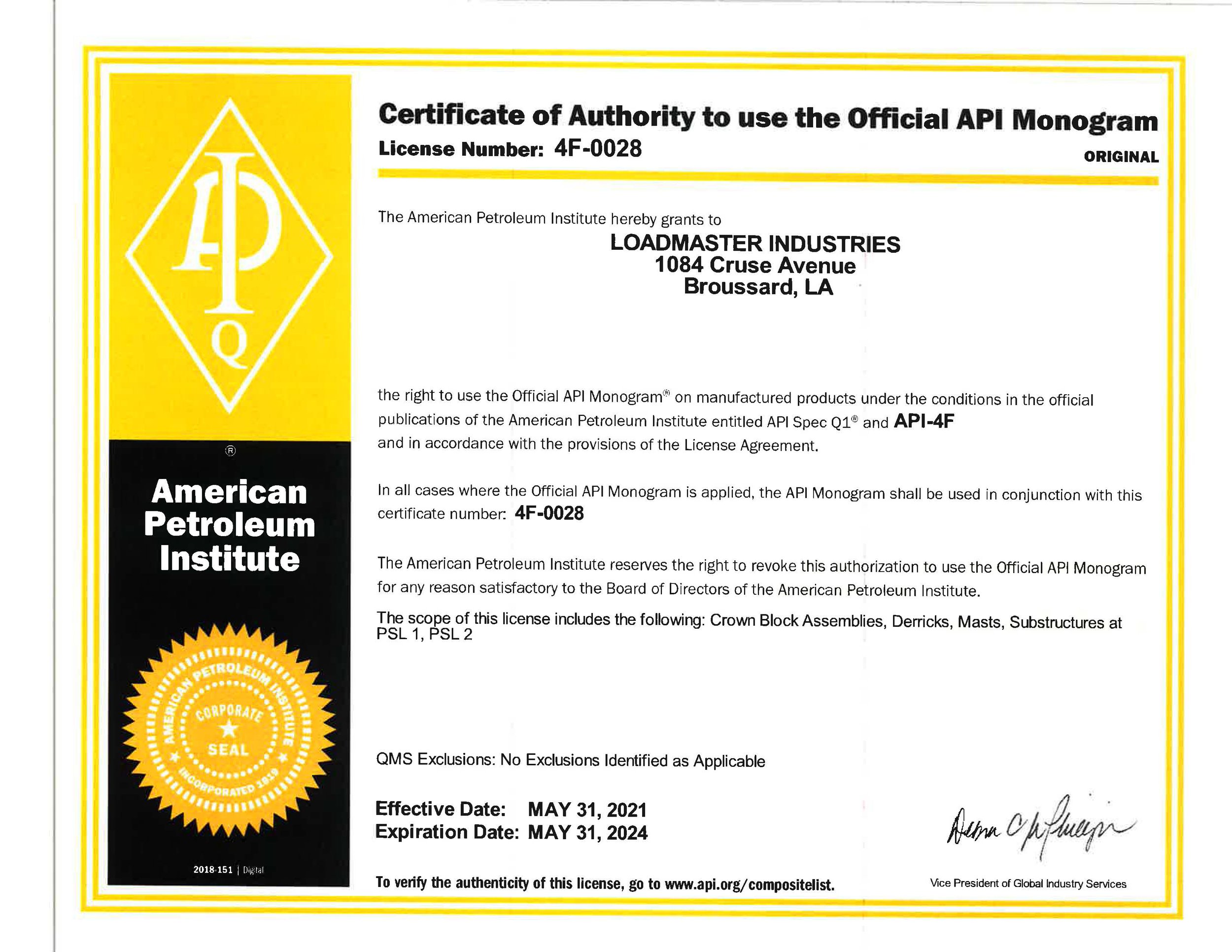

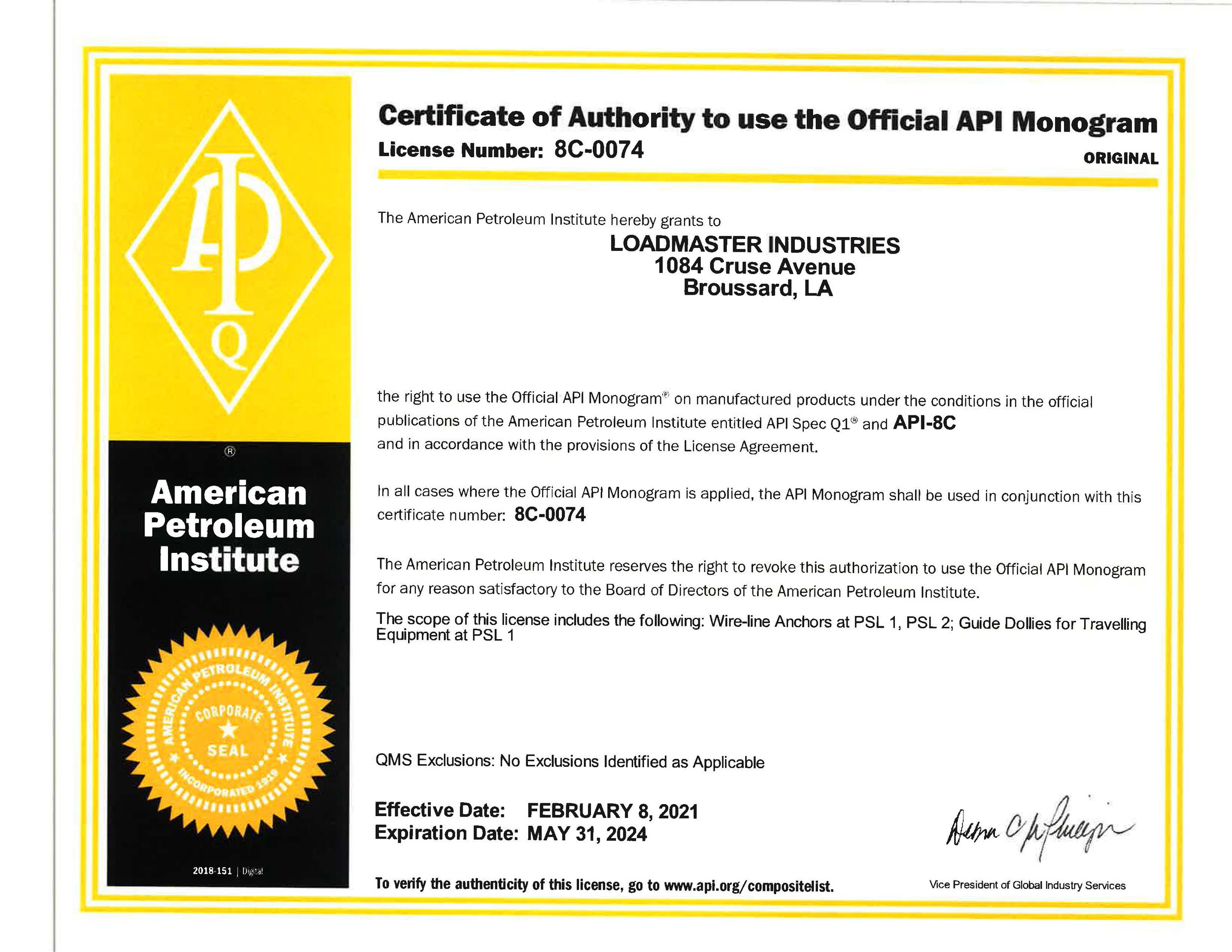

With a Quality System accredited by ISO 9001-2015 and API Spec-Q1, Loadmaster’s Quality Department is committed to providing high quality, reliable products that meet and exceed customer specifications.

Loadmaster is one of the longest tenured facilities for API 4F, covering PSL1 and PSL2. We have held and utilized our license for manufacturing over 100 Monogrammed Drilling Structures over 23 years.

Certifications

Mission Statement

Our Mission is to provide valuable turnkey solutions for our clients in a culture where employees and shareholders goals are achieved with a focus on Quality, Health, Safety, and the Environment

QC & Traceability

Loadmaster provides customers with Full Material Trace-ability in a data book which includes: MTR’s, assembly drawings, weld maps, inspection reports, welder certifications and any other product quality documentation per our customer’s specific needs.

All materials and parts must pass a multi-stage inspection process before being allowed to enter and proceed through fabrication.

With trace-ability being of such high importance, Loadmaster tracks all areas of concern within an advanced ERP system. MTR’s, welder’s logs and NDE logs are all tracked and attached to our ERP system.

Safety

Loadmaster maintains the highest level of standards with regrades to Health Safety and Environmental. This represented by the numerous Louisiana Workers Compensation (LWCC) “Safest 70 Awards” presented in consecutive years.

Loadmaster participates and maintains an approval rating within all industry standard safety programs; SEMS, ISNetworld, DISA, and NCMS.

Safety work compliance, JSA’s, companywide and visitor stop work authority, regular safety audits, employee safety training, visitor safety training, daily, weekly and monthly safety forums all contribute the HSE atmosphere built for success at Loadmaster.